Take control of your plant floor with an elastic MES system that meets you where you are today with a modular architecture that scales across locations and a simple platform that brings together more capabilities than a traditional MES to help unlock autonomous operations.

What is a Plex MES System?

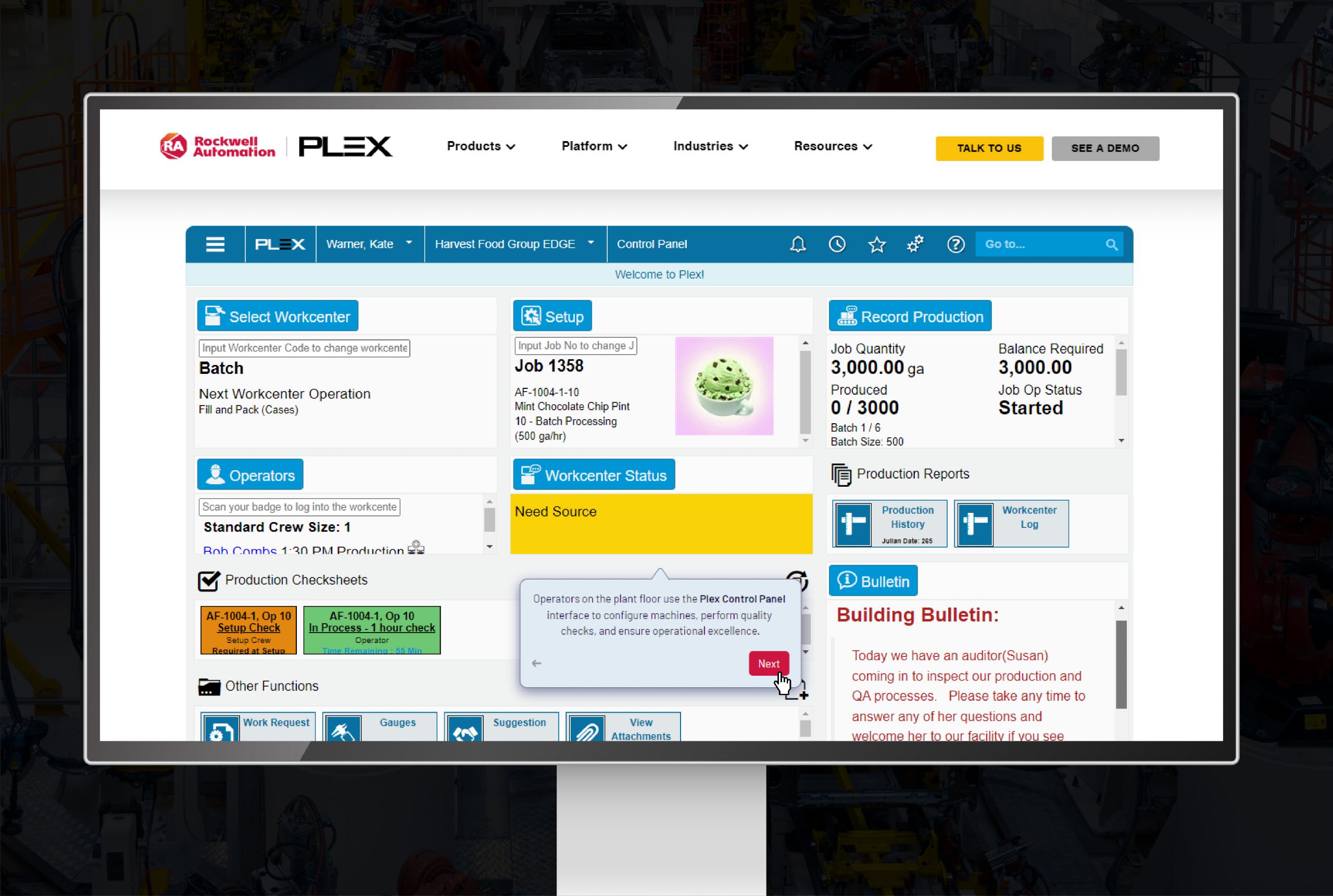

Plex MES (Manufacturing Execution System) is a cloud-based production management platform that gives manufacturers full visibility across the plant floor and real-time control over production lifecycle. Plex MES features operator control panels, error-proofed workflows, closed-loop quality control, inventory tracking, and finite scheduling, all aimed at reducing errors, increasing efficiency, and improving quality. By connecting tightly with ERP systems and providing unified, real-time data, Plex MES helps manufacturers achieve compliance, traceability, and consistent performance across operations. As a truly elastic MES, Plex enables you to quickly deploy the capabilities you need today with broad options to seamlessly scale as your needs change.

Benefits of Plex Elastic MES Software

Gain control without compromise

Accelerate time to value with a rapidly deployable, modular architecture, choosing the capabilities you need today and making changes flexibly as your needs evolve.

Simplify operations at scale

Build on a platform that is scalable and centrally managed to simplify operations across locations, reducing costs and supporting business growth.

Unlock autonomous operations

Connect and unify more capabilities within your MES platform, unlocking broad data visibility, laying the foundation for AI, and moving your organization towards 'lights out' production.

Plex MES System Capabilities

Aligned with extreme precision to the pillars of Smart Manufacturing.

Plex MES/MOM Systems are designed to provide immediate value for your company, while preparing you for whatever tomorrow brings.

Connect

Connect to operations with a platform designed to support the speed, volume, and complexity of manufacturing transactions.

Automate

Automate production transactions and manual tasks to ensure greater accuracy and free up workers’ time for higher-value activities.

Track

Track materials effectively throughout the entire journey, from receipt to shipment – including WIP – to deliver a real-time, granular view of the business.

Analyze

Analyze data collected at each manufacturing moment in the context of your enterprise-wide goals and metrics.

Explore Plex MES Platform Features

Production Finite Scheduling

Use a finite scheduling engine to determine which jobs to schedule to which work centers, with resource availability in mind.

Closed-Loop Quality Management

Maintain quality procedures directly from the control plan for increased process repeatability and predictability.

Inventory Management

Track and manage your inventory in real time, and stay in control with end-to-end traceability.

Production Management

Stay on top of plant floor operations—making the right quantity of the right product at the right time for improved OEE (overall equipment effectiveness).

Human Capital Management

Empower frontline manufacturing teams with real-time digital tools to improve productivity, reduce errors, and enhance collaboration.

Unified Edge to Cloud

Lower total time to value and total cost of ownership with the only SaaS MES platform that offers flexible deployment options tailored to your business needs - from being 100% cloud-native to having a fully resilient edge, an elastic MES keeps manufacturing running, even during disruptions.

Featured MES Resources

MES Manufacturing Software FAQs

What is manufacturing execution system software?

Manufacturing execution system software is a digital platform that monitors, tracks, and controls production processes on the shop floor in real time. An MES connects machines, people, and data to optimize efficiency, quality, and traceability throughout manufacturing operations.

Why is MES software important for manufacturers?

MES software is essential because it helps manufacturers reduce errors, improve compliance, and increase productivity by delivering consistent, data-driven processes. It provides real-time visibility into production, enabling faster decisions and better control over costs, quality, and delivery.

What is the difference between composable MES and elastic MES solutions?

The role of MES is evolving and, even among modern solutions, many MES platforms are simply not flexible to fulfill the evolving needs of modern manufacturing. An elastic MES simplifies operations at scale, with a centrally managed platform that cuts costs, while offering built-in cybersecurity, compliance and resiliency. This platform encompasses more capabilities than a traditional MES solution, unifying data, optimizing processes and moving organizations towards autonomous operations.

Plex MES offers the following elastic qualities:

- Industry DNA at the core – Pre-configured for Discrete, CPG, and regulated industries with compliance, traceability, and security built in.

- Flexibility beyond traditional systems – Elastic MES delivers intelligent capabilities with logical on-ramps to the smart manufacturing platform of the future-from workforce management and quality to production control, supply chain, and business operations.

- End-to-end IT/OT integration – Enabling real-time decisions and operational agility through a truly holistic portfolio and product offerings.

- Extensible and interoperable platform – Encouraging seamless technology integration to external systems, with the flexibility to build unique business flows within a no-code environment.

- Resilient edge-to-cloud connectivity – Combining cloud agility with edge resiliency to keep operations running, even during disruptions.