Avon Machining was operating in silos. Company departments, including engineering, production, quality and accounting, each had its own Access databases and Excel spreadsheets. Databases were not integrated with each other, which made tracking, retrieving and communicating critical data very difficult and time-consuming.

Business Challenges:

- Avon Machining was operating in silos—engineering, production, quality, and accounting had separate spreadsheets and databases.

- Trying to compile data was complex and time consuming.

- Errors in data entry, tracking, and reporting meant the company had no confidence in the data to gain a picture of how the company was performing.

At A Glance

- 20% growth average over 10 years with real-time visibility and tracking

- Reduced time to prepare shipping reports from two and a half hours down to 30 minutes

- 98% inventory accuracy—inventory count was off by an average of 7% before Plex

Plex allowed us to manage operations efficiently with the minimum resources required. Without Plex, we wouldn’t have been able to handle the company’s impressive growth.

Company management realized that it needed a solution that could seamlessly integrate across the enterprise and provide easier access to real-time information. After reviewing and testing several options, the Plex Manufacturing Cloud® was selected because of its ability to connect and manage all areas of manufacturing operations.

“Plex is the most versatile solution to use in a manufacturing environment,” said Matt Korth, President at Avon Machining. “It helps us stay organized and suits our growing needs.”

Gaining Visibility for More Efficient Cost Management

Comprehensive, accurate, and timely information enables Avon Machining to efficiently manage costs and resources. The Plex Manufacturing Cloud tracks and records all physical events including production, inventory status changes, receiving, subcontracting, shipping, and other data on the shop floor.

“Honestly, we would not be where we are without Plex,” explains Korth. Avon Machining has experienced an average of 20 percent growth in the last 10 years. Even during the economic downturn, the company maintained a steady growth.

Before Plex, production was recorded at the end of the day. There was no way to know the number of parts produced per hour, number of discrepant parts, number of parts that were reworked or related production costs. Now employees simply log in at their workcenters and record production details in real time. For example, if an employee makes five parts in one hour, he or she logs that detail at the end of the hour. Real-time tracking enables employees to identify and label defective parts earlier and send them for correction before they move farther along the manufacturing process.

“This enables our employees to better focus on daily production, saving time and reducing errors,” explained Korth.

Shop floor managers now have the tools to better calculate costs by retrieving important information such as:

- Quantity of parts produced

- Production time for each part

- Time for total production

- Quality of the produced parts

- Number of parts with issues

- Time spent by the operator and the associated cost

“Drill-down data within Plex helps us from a cost standpoint,” said Korth. “We run the costing function to get the cost associated with each part and each activity. We know where and how to utilize our resources efficiently and are able to make better business decisions.”

Saving Time with Better Tracking

Avon Machining outsources some production parts to smaller local companies. Previously, if there was an issue with a part sent by the supplier, tracking the part to the supplier for rework purposes was a time-consuming chore. It was challenging to know the status of the rework without a great deal of effort.

The Plex Manufacturing Cloud enables employees to identify parts that need rework in two simple steps. Based on the serial numbers, employees can identify defective parts, flag them, and send them for rework.

Prior to Plex, shipping reports were prepared manually, taking about two and a half hours. It involved printing the customer release and manually checking the status, the physical location and quantity of the requested part. Now, all required data is readily available in real time, reducing reporting time to just half an hour.

“One of our goals is to have our raw materials suppliers use Plex,” said Korth. “Parts will then be entered into our system before they even ship to us. They will be scheduled and ready to move to the workcenter as soon as they come in the door.”

Maintaining Accurate Inventory— and Steady Growth

Avon Machining has connected all functions of its operation with the Plex Manufacturing Cloud included inventory management. Before Plex, the inventory count was off by an average of seven percent. With better tracking and inventory management functions, it is now only off by two percent.

“We have accurate data, such as inventory numbers and the production percentage of parts at our fingertips at all times,” explained Korth. “Plex allows us to track production numbers, costs and capacity easily and quickly.”

The availability of real-time data enhances the reporting and forecasting capabilities of managers. On the shop floor, the production status screen at each workcenter is automatically updated every three minutes, allowing the foreman to check the status and catch any issues in a timely manner.

“Plex allowed us to manage operations efficiently with the minimum resources required,” Korth continued. “Without Plex, we wouldn’t have been able to handle the company’s impressive growth.”

About Avon Machining

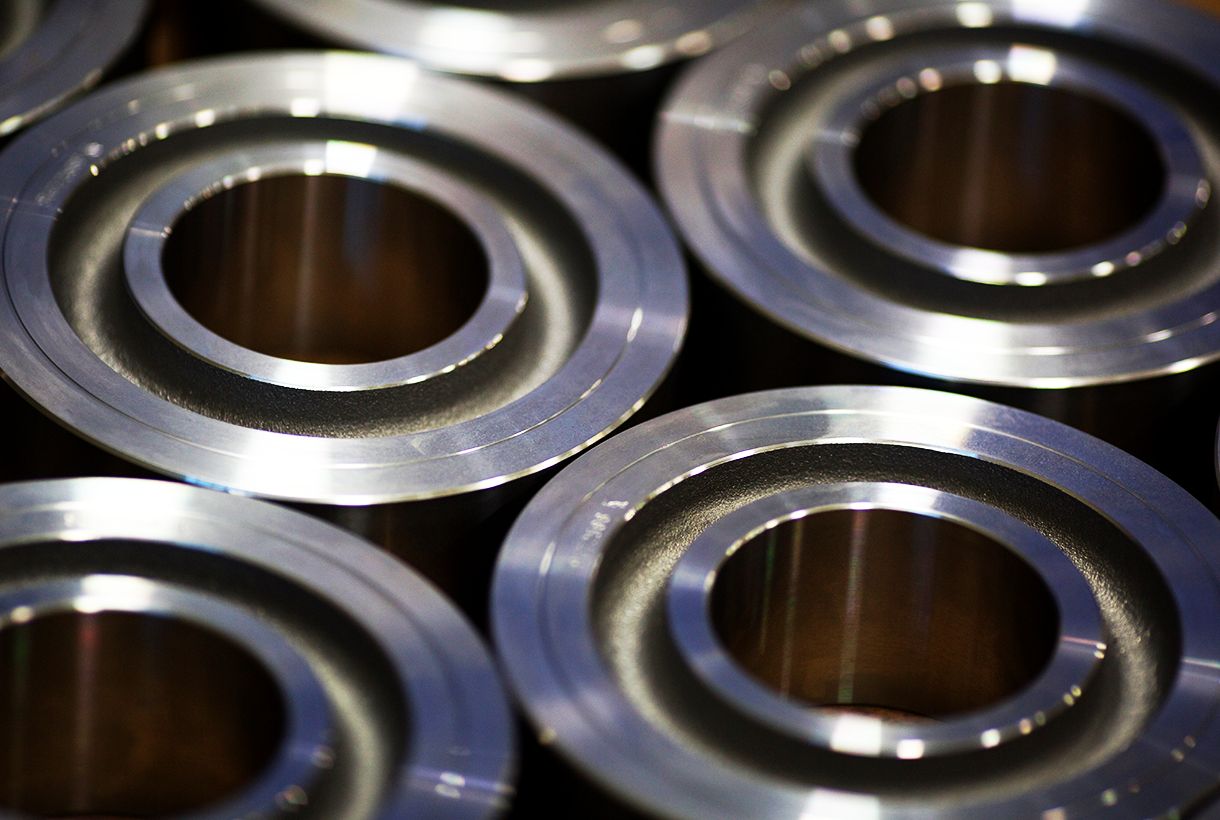

Headquartered in Shelby Township, Avon Machining manufactures precision-machined components and subassemblies for heavy industrial equipment manufacturers in North America and beyond. Avon Machining acquired the assets of Avon Gear in May 2017.

Industry: General Manufacturing

Location: Shelby Township, MI

Published May 30, 2014

Featured Resources