Plan it, Schedule it, Dispatch it with Plex

Better determine requirements for materials and capacity while ensuring efficient use of production assets for more lean production practices.

Our manufacturing planning and production scheduling software features keep inventory levels low and costs at a minimum. Plan for the optimized capacity utilization of your plant floor resources with lean and efficient production management.

Manufacturing Production Planning & Scheduling Capabilities

- Quickly calculate recommendations for what’s needed, how much is needed, and when it’s needed with MRP to keep inventory levels and cost at a minimum.

- Optimize manufacturing production runs, alleviating major cost and time conflicts in the process.

- Utilize multiple advanced manufacturing production scheduling options to level-load production across alternative work centers.

- Make advanced production planning and scheduling trade-off decisions considering finite capacity and available resources.

- Set accurate expectations by providing customers with a reliable delivery date based on actual availability of resources.

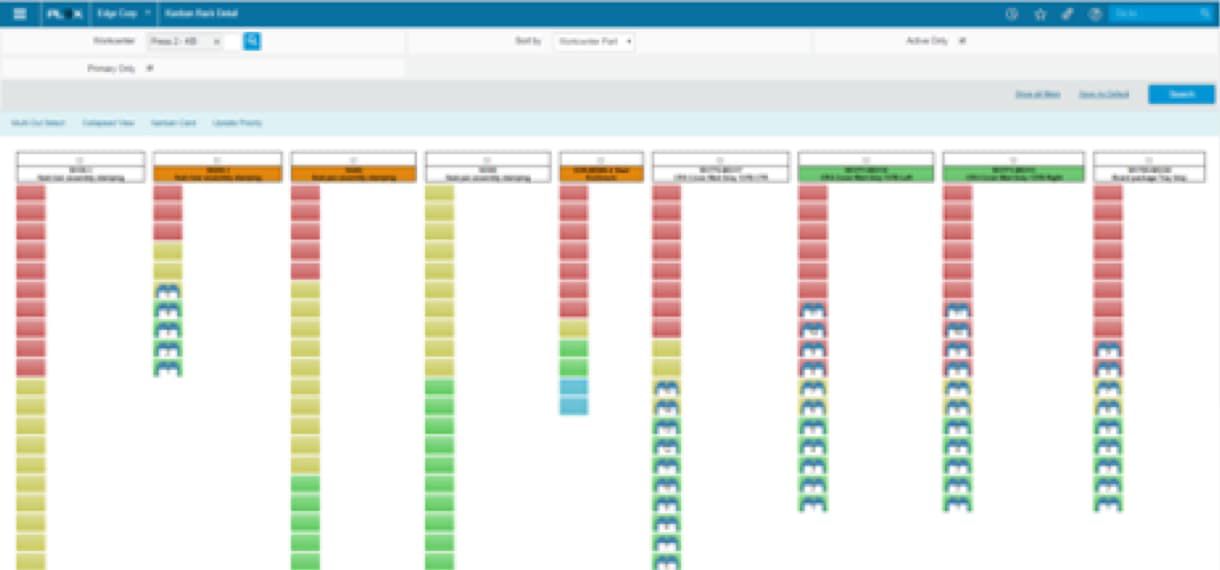

- Use Kanban to support pull-based demand for lean operations that eliminate over-production waste.

Plex MES/MOM Production Scheduling Capabilities

Production Management

One of the many Manufacturing Execution System (MES)/MOM features you'll find on the Plex Smart Manufacturing Platform, production management “operationalizes” production with inherent error-proofing to control your production processes. Create a culture of control and continuous improvement, where Plex helps you orchestrate the many moving parts in your production environment for optimal performance. See how to manage complexity with efficient production scheduling and a unique Control Panel that gives you real-time visibility all the way to your plant floor equipment.

Plex “operationalizes” production with inherent error-proofing to control your production processes.

Discrete Manufacturing Capabilities

- Reduce errors and improve quality with direct connectivity to plant floor automation.

- Enable operators to resolve production issues in real time for greater productivity.

- Leverage a unique, touchscreen Control Panel for capturing production, maintenance, and tooling data.

- Access production data from anywhere using mobile devices through SmartPlex.

Process Manufacturing Capabilities

- Eliminate multiple systems with a common Control Panel to capture equipment and production information automatically.

- Easily identify the value of your work-in-progress inventory at any time with Plex Costing.

- Put data collection and ownership in the hands of your operators to resolve production issues themselves for better accuracy and accountability.

- Provide real-time visibility and accumulation of actual and standard costs at each step of the production process.

Plex MES/MOM Production Management Capabilities

Featured Resources