In the fast-paced world of manufacturing, operator error and inefficient work steps are not just minor setbacks; they are significant hurdles that can derail production schedules and inflate costs. The complexity of modern manufacturing demands precision and consistency, yet human factors can introduce variability that compromises both.

Operator errors often arise from misinterpretations, static instructions, and legacy procedures, leading to defective products, safety incidents, and costly rework. This is particularly true for new hires who face the daunting task of mastering complex production steps without adequate orientation and support. The challenge is exacerbated as veteran operators retire, taking their invaluable expertise with them.

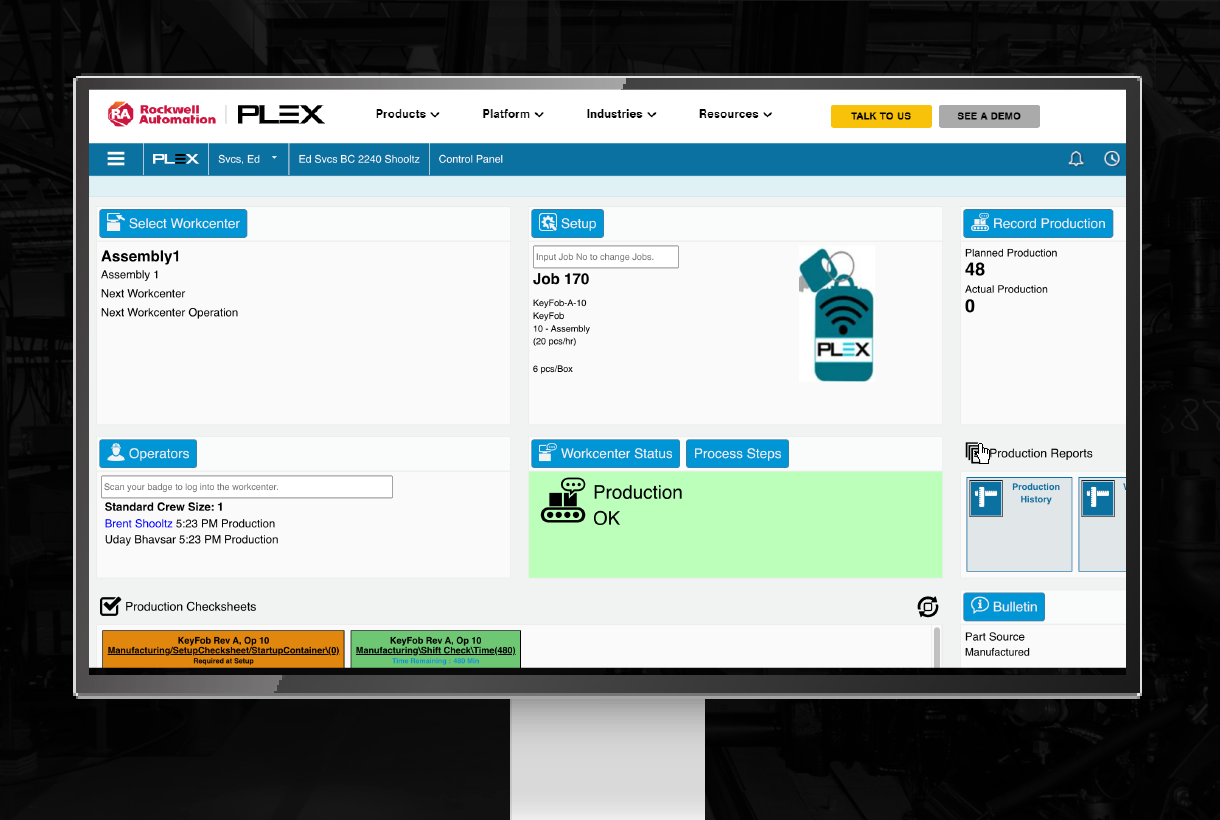

Plex Guided Work Instructions help combat these challenges head-on. Our platform transforms the way operators interact with work instructions, offering a digital, dynamic, and interactive guide that adapts to the task at hand. Here are the advantages:

- Clarity and Precision: Guided work instructions provide crystal-clear guidance, reducing the likelihood of errors and ensuring each step is performed correctly.

- Real-Time Updates: As processes evolve, operators can receive real-time notifications of quality alerts and changes, keeping them informed and in sync with the latest methods.

- Knowledge Preservation: Capture the expertise of your most experienced operators and preserve critical knowledge.

- Enhanced Onboarding: New operators can be trained more effectively with interactive guides, images, and visuals to accelerate learning and competence.

- Continuous Flows: By integrating setup instructions into the workflow, operators have access to uniform and standard flows, helping them smoothly transition from one task to another without delays.

- Data-Driven Insights: Valuable data on operator performance is easily captured to measure process efficiency and enable continuous improvement.

Click through this short demo to learn how Guided Work Instructions in Plex can help you boost operator efficiency, ensure product quality, and uphold the highest standards of operational excellence. It’s time to embrace a future where every action is informed, every task is optimized, and every product embodies the highest manufacturing quality.

Related Content