Results

- Enhanced visibility and accountability throughout the production process

- Improved access to and trust of production data

- Increased view of production records and movement

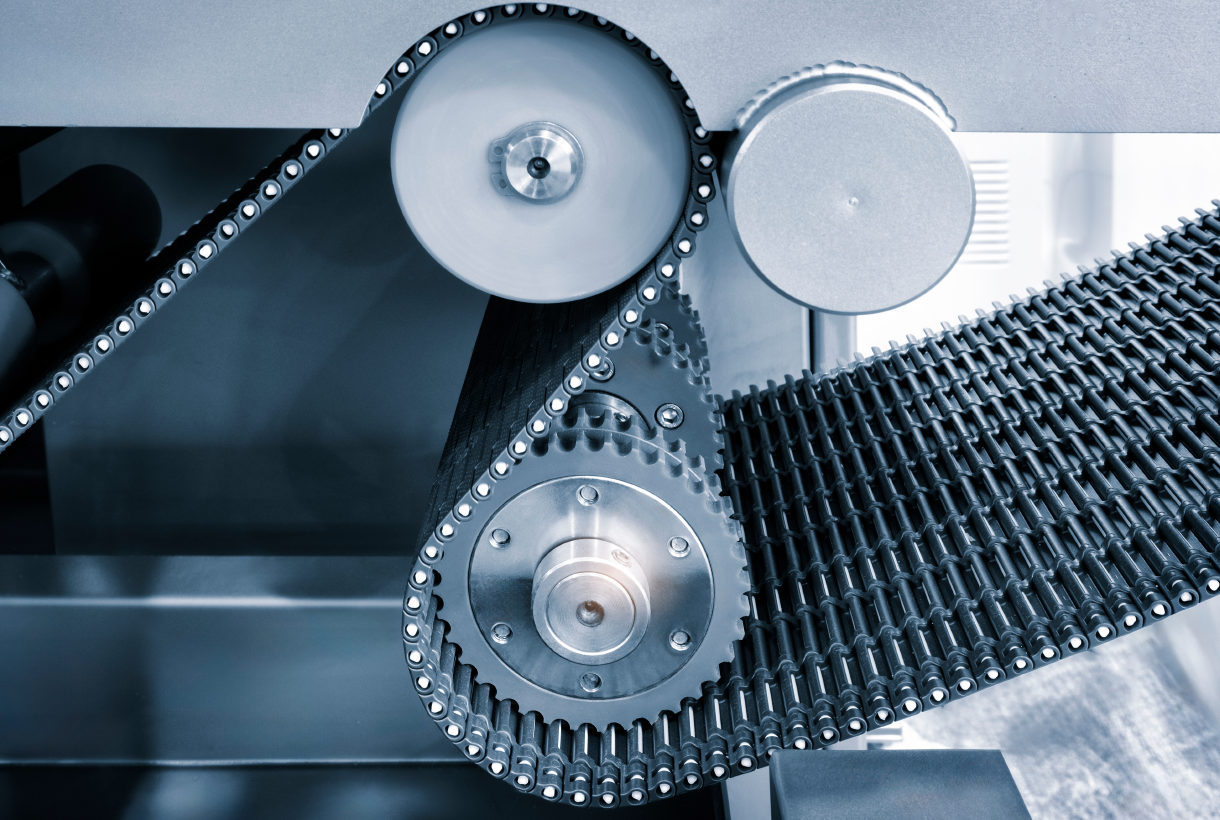

Founded in 1965, Allied-Locke Industries began producing steel detachable chains for the agricultural market. Through a 1978 acquisition, the company expanded its offerings and became one of the major producers of agricultural chains in the United States. With additional acquisitions and expansions over the years, Allied-Locke now has three manufacturing plants in the United States and offers five different production divisions, including Agricultural Chain, Precision Roller Chain, Industrial Chain, Environmental Products, and Sprockets.

Having used a highly customized legacy system for many years, Allied-Locke employees were comfortable with what they knew best. However, this system was heavily dependent on paper printouts for order information and production jobs, which proved itself to be increasingly problematic overtime. Not only did the team face a lack of digitization, but they also experienced limited plant floor visibility and untrustworthy data. Maintenance and tech support had already been outsourced to third parties and with the legacy system running on an outdated server, the Allied-Locke team saw a need to find a new solution.

Speed and reliability were major players in the search for a new ERP system and the team needed improved insight into sales, purchasing, and production history to better serve their customer base. Additionally, Allied-Locke was interested in exploring the capabilities of a cloud-based system. After experiencing a ransomware attack in 2020, which halted data entry for two weeks, a key motivator in the hunt for a new system was the promise of both security and accessibility with cloud storage.

The Allied-Locke discovery process began internally—Tucker Shoemaker, ERP Administrator and Product Engineer, was appointed to explore ERP solutions. Knowing the company had operated under the previous system for over 20 years, Shoemaker understood that the transition would be challenging despite being necessary. During the evaluation process, Plex stood out specifically due to the production tracking and accessibility. The Allied-Locke team was also impressed by Plex’s customizable pages and settings that would allow them to configure the system to meet their needs.

Easing the Team into Plex

Ultimately, Plex was chosen as the best ERP solution for Allied-Locke and the transition process kicked off in April 2023. Initially, the team planned for a six-month implementation but opted to extend the timeline to balance production and sales while Plex was integrated.

To ensure success, the company included many employees in the transition process. Team members managed new locations and work center codes, while managers from purchasing, sales, production scheduling, and accounting made configuration decisions. Production managers selected leads for control panel use and inventory workflows, and Shoemaker handled shipping and receiving. However, he noted that, in hindsight, he would have included even more participants to help everyone better understand Plex’s benefits.

The transition itself was a significant undertaking—approximately 60% of the steps within Plex were entirely new to Allied-Locke. The team initially worked in both the legacy system and Plex simultaneously, allowing employees to familiarize themselves with the new system before going live, which eased the process. The greatest challenge was shifting the mindset of employees to embrace Plex’s benefits rather than comparing it to the legacy system. This was ultimately alleviated through firsthand experience within Plex, time, and hands-on learning.

Even with the initial hesitance, the team came together to carry out a successful transition to Plex. This success was found through repetition, learning, and dedication to the system, with hands-on practice and integration of Plex with the existing infrastructure playing a major role. Shoemaker stated, “At the end of the day, we all came together, saw Plex for what it was, and were able to make it work for us. I would say that it was a success all around.”

Post-Implementation Success

Upon completion of the Plex implementation, the team noted significant changes. Plex enforced structured locations for storage and holding areas, a new feature that eliminated the need for employees to spend 15-30 minutes searching for parts on the shop floor. One of the biggest benefits seen was the improved speed and reliability. The legacy system was out of date and the software was slow, freezing frequently and causing delays. With Plex, Shoemaker noted, “Not only can I backtrack through multiple pages to acquire the information that I’m looking for, but I very rarely have to worry about any software issues or crashes.”

Plex also enhanced visibility and accountability. Employees became more involved in data entry, ensuring that up-to-date information was accessible to everyone. Initially, the shift from paper to digital was a learning curve, but over time, the team recognized the power of increased traceability. Though data accuracy is still improving, the company took the opportunity to rebuild process routings from scratch rather than transfer incorrect data from the legacy system when the implementation began. This has led to increased trust in Plex as accuracy continues to increase.

Specific features stood out following the implementation, like Plex’s search capabilities and the customer release and scheduling screen. The search system and filters are new, compared to the Allied-Locke’s legacy system, and the customer release and scheduling screen gives employees a comprehensive view from manufacturing to shipping to sales. Additionally, team members can now make use of Plex’s container history, which allows everyone to track issues on the shop floor with ease.

The implementation not only improved processes, but it also helped team members see the benefit of modern solutions firsthand. Having worked with an outdated legacy system for so long, many Allied-Locke team members were unaware of the modern capabilities available within updated ERP systems. Specifically, the ability to track individual serial numbers from raw materials to finished goods. Shoemaker noted, "Functionality alone can turn a 3-hour morning fiasco into a 5-minute solution.”

Allied-Locke’s transition marked a significant leap forward in efficiency, reliability, and data accessibility. The company moved from an outdated and inefficient system to one that provides real-time data and improved visibility. By embracing change despite initial hesitation, Allied-Locke has positioned itself for a more efficient and data-driven future that will continue to enhance productivity as they explore Plex and its full potential.

Allied-Locke

Based in Dixon, Illinois, Allied-Locke Industries is an American supplier of precision roller chains, agricultural chains, environmental products, sprockets, and more. After nearly 60 years of business, the company has expanded significantly, with its primary manufacturing facility spanning nearly 675,000 square feet. Two additional plants in Illinois and Mississippi allow the company to serve a wide array of industries and meet customer needs through excellence in quality and service.

Location: Dixon, Illinois

Featured Resources