Off The Cloud & Paper-Based

Located just ten miles southwest of Pittsburgh, Pennsylvania-based Tech Met Inc. is a chemical milling company that primarily services the medical and aerospace markets. The company has been 100% employee-owned since 2015, transitioning to an Employee Stock Ownership Plan (ESOP) after their founder, Gary Reed, retired. With core company values of honesty, fairness, and hard work, every team member at Tech Met is committed to the success of the organization. As a service provider, Tech Met is positioned uniquely in the chemical and metal sector. The company typically receives parts from their customers, resurfaces the material to supplied prints, and sends the product back out. Their client base is diverse; customers can have just one part or hundreds. In its entirety, Tech Met services thousands of parts and keeping track of each piece, along with its specific processing history, is critical.

At A Glance

- Reduced monthly production close out from 4+ weeks to 2-3 days

- Decreased invoicing time from 1 week to 1 day

- Digitized paper-based processes and record keeping

- Gained real-time inventory and revenue insight

Before Plex, we were siloed and unconnected. We were managing everything appropriately, but we were paper-based and doing lots of documentation rework. After Plex, many of those pain points are gone, there’s less paperwork, and we can realize revenue quicker. We have access to a vast amount of data and can catch errors much quicker than we had in the past.

Tech Met expanded quickly over just a few years, growing from a handful of customers to adding larger-name clients onto their roster. While the growth was a milestone worth celebrating, the company knew they needed a system in place to sustain their success. Eager to improve, Tech Met listened to the feedback of their customers and knew it was time to start looking for a modern ERP system. The company had clear pain points they needed their new system to address: lack of digitization, plant floor visibility, and real-time data. There was no single source of information for the company to operate from and most of their processes were tracked across various spreadsheets. Ideally, their new ERP system would digitally connect their workforce and provide production clarity.

As an aerospace contractor, Tech Met is required to keep production and quality documents for up to 30 years. This is a vast amount of documentation for any company to keep, especially when its primarily paper based. Certain documents were stored off-site and could be difficult and time-consuming to retrieve. With no digital ERP system in place, production visibility was provided by word of mouth – although Tech Met has a committed and talented team, there were opportunities for details to slip through the cracks. It was clear the company needed to digitally transform and develop a reliable business system that both employees and customers would be able to depend on.

An Unexpected Implementation Journey

Ahead of making any decisions, Tech Met put together a small taskforce focused on finding the best ERP solution for the company. Their search consisted of several rounds of vetting, reviewing various solutions available on the market and seeing how they could meet the company’s growing needs. After a recommendation from their managed service provider, the company set their sights on Plex – it was Plex’s hands-on approach that set their software apart from the crowd. With the help of System Integrator (SI) Control+M Solutions, Tech Met participated in demos that showcased how Plex could fit within their existing infrastructure. The value of Plex was clearly demonstrated to Tech Met and the company was eager to move forward with the cloud-based smart manufacturing solution.

The Plex implementation project officially kicked off in the beginning of 2020, dedicating a similar team to facilitate the process. Tech Met also worked alongside a project manager from Control-M Solutions, who they credit as playing a vital role in their implementation journey. Despite having all parties aligned, Tech Met’s implementation took a sharp turn when faced with the global COVID-19 pandemic. Considered an essential business, Tech Met was mandated by the government to remain open. This created competing priorities and the company experienced unprecedented challenges—as a result, their initial implementation timeline was delayed. A small but mighty business, Tech Met pushed forward in the face of uncertainty.

In 2021, as the company started to emerge from the pandemic, Tech Met renewed their dedication to go-live with Plex. The company worked once again with Control+M Solutions to stay on track and to ensure a seamless transition to their new ERP system. The biggest task was figuring out how to transfer customer data from their current system into Plex – it quickly became apparent that having individual process routers for each part was not feasible. Instead, Tech Met transferred their production steps in bulk. This decision sped up their implementation and generated positive project progress. There are currently over 2,000 parts in Plex and still more to go as Tech Met continues to integrate their processes. Although their implementation journey was longer than expected, Tech Met was able to successfully go-live on October 2nd, 2023.

Streamlined Success With Plex

In the past year, Tech Met has experienced numerous benefits from migrating to Plex. Previously, Tech Met was largely paper-based and important documents were stored in multiple locations. Now, production and quality documents can be accessed in real-time through Plex and—due to Plex’s cloud-based nature—these documents can be accessed anywhere. One of the biggest improvements has been Tech Met’s visibility into revenue and automating customer invoicing. Prior to Plex, production invoicing would take over a month to close out. Now, production closeout takes only a few days. Additionally, Tech Met can now bill customers instantly after a job has been shipped. When invoicing was completed manually, generating customer invoices could take over a week or longer. With Plex, this no longer happens, saving the company money and allowing revenue to be realized.

"I can say with complete certainty that [Plex] has paid for itself, several times over... I am positive it’s saving us money.” - Robert Vaccaro, Technical Services Manager, Tech Met Inc.

In general, data is now both accurate and easily accessible. Before, due to lack of insight, inventory could sit and remain unassigned to a job. Now that employees have a better view of what products are in the facilities, they can more efficiently utilize on-hand inventory. This visibility has created a culture of trust within Tech Met, winning over even the most hesitant employees at the company. Those who had previously worked with ERP systems adapted to Plex quickly and with relative ease. If others needed a little more time, it was simply because change requires adjustment. “Once I get someone to open up the system and do the work in Plex – everything gets simpler. Any complaints go away,” shares Vaccaro. He believes that having visibility into stable revenue numbers and reliable data has allowed employees to see the value of Plex.

As the company looks ahead, there are plans to continue growing and optimizing their business. With Plex, Tech Met hopes to implement Plex MES and QMS, continuing to automate their processes and streamline quality data. The company is still transferring data into the Plex system,working diligently to integrate those parts and reap the benefits of having that material live in one spot. Additionally, Tech Met is still working to fully integrate production planning into Plex. This integration would allow the Tech Met team to benefit not only from production visibility but gain even more plant-floor visibility. With a successful year under their belt, Tech Met is excited about what else is in store with Plex.

About Tech Met

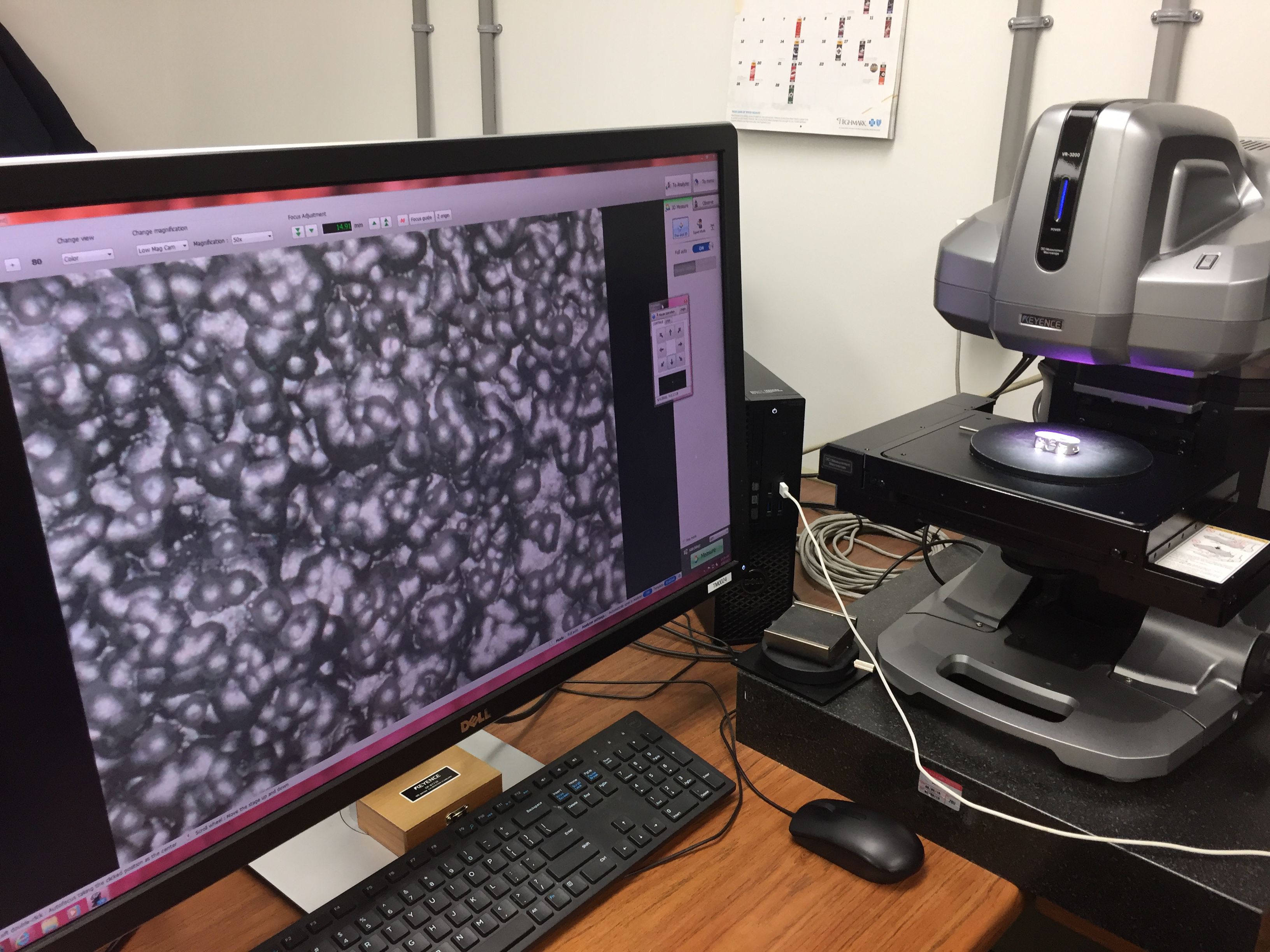

Tech Met Inc. is a leading provider of advanced chemical post-processing and surface treatments for the world’s most advanced additive manufacturing applications. Specializing in high performance metal alloys, Tech Met has served the aerospace, medical, industrial, and commercial markets with unprecedented precision and quality since 1988. From aircraft engine components to spinal implants, Tech Met's process control, lean practices, and six sigma certified project managers deliver quality assured products that meet the most rigorous specifications and are Nadcap AS7004 & AS7108 certified.

Industry: Metal

Location: Glassport, Pennsylvania

Published December 15, 2024

Featured Resources