Overview

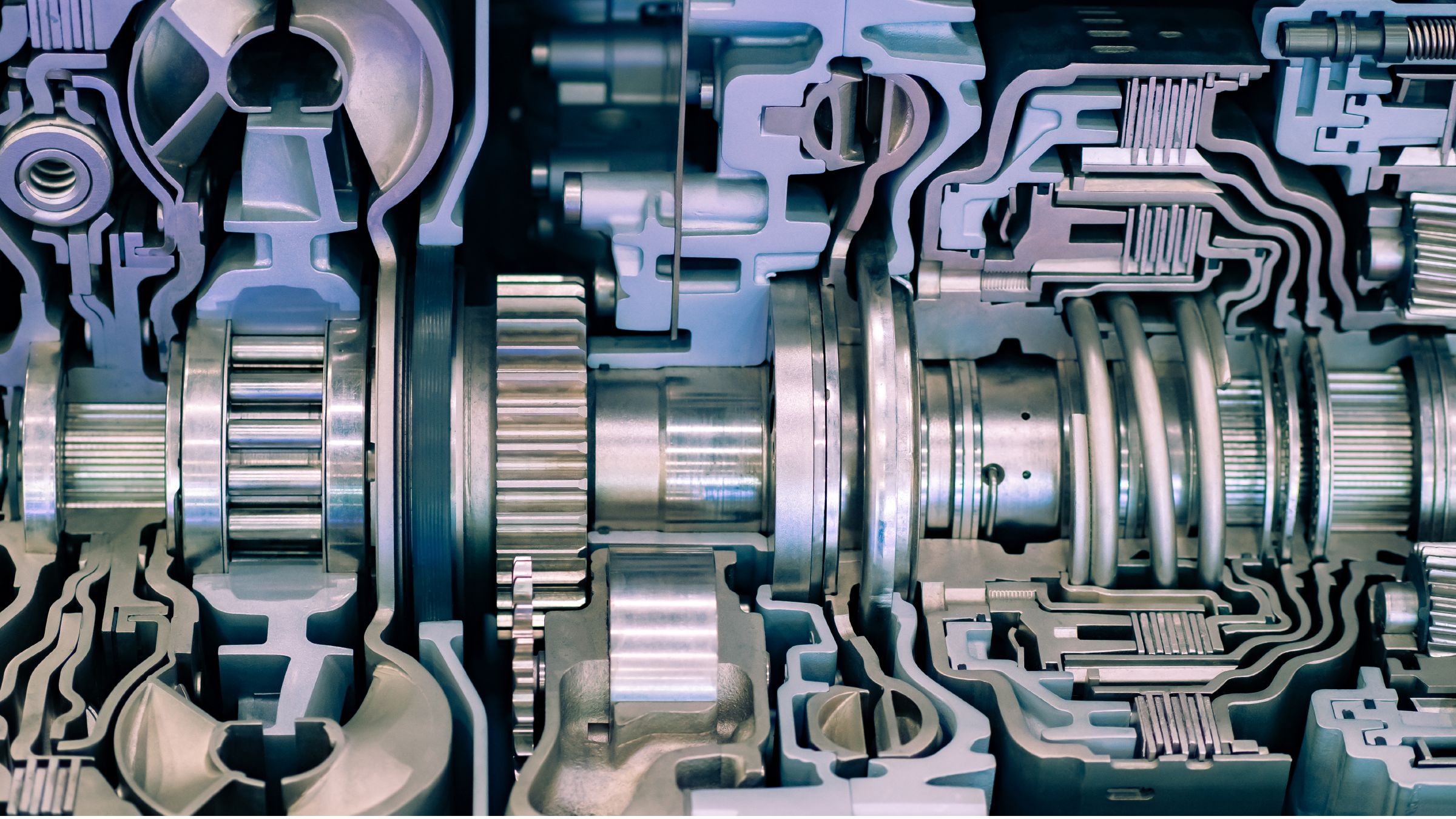

Bayrak Technik GmbH specializes in the development and manufacture of thermoplastic, elastomer, and metal components for interior, exterior and chassis applications in the global automotive industry, and for sealing technology in the sanitary (medical) and construction industries.

With four manufacturing plants in Germany, it was seeking a tightly integrated, multi-module enterprise software platform that would collate, analyze, and share operational data for more accurate inventory control and enterprise resource planning (ERP).

Its deployment of the Plex Smart Manufacturing Platform from Rockwell Automation not only creates a stable foundation for its own ongoing digital transformation, but also establishes a strong anchor point for integration of its data into its customers’ downstream operations, as the adoption of end-to-end digital chains gains momentum across global markets.

- German thermoplastic, elastomer, and metal component manufacturer identifies the need for a unified approach to quality, planning and inventory control

- Plex Software – ERP, QMS and MES modules

- Tighter inventory control

- More accurate production planning

- Better asset integration

- Improved operational-data analytics and deployment

- Improved quality and sustainability through machine monitoring

- More empowered employees with actionable real time insights

- More accurate information for digital chain

Challenge

Bayrak’s adoption of the Plex software suite was driven by both internal requirements and external market-driven demands.

According to Johan van der Werf, chief information officer at Bayrak Technik GmbH: “Not only did we need to gain wider and better control over our production processes, but we also wanted to tighten up our inventory control, as stock-take discrepancies could impact scheduling and capacity. We also identified the need to pull various information sources together to create a single, unified window into our manufacturing operations.”

Compounding these day-to-day operational pressures was a request from one of its major customers – a multinational automotive OEM – for access to Bayrak Technik’s machine data to complete a digital chain. “This customer was the first with this type of request,” van der Werf explains, “but we knew it would not be the last, so to answer both sets of challenges we knew we needed a strong, scalable and widely deployable smart manufacturing platform.”

Solution

Van der Werf says: “I had experience of the Plex ERP module, where I had overseen its deployment in one of the first EMEA-based applications at facilities now owned by Bayrak Technik, back in 2015. Following some localization modifications that adapted the software for EMEA finance and tax models, the software successfully went live at a plant in Germany, followed by plants in Czechia and Poland.”

The Plex suite proved its capabilities. “It worked well, and everyone quickly picked up how to use it,” he explains. “And when Plex was acquired by Rockwell it gave us even more confidence to take the next steps at Bayrak, which would see the deployment of the manufacturing execution system (MES) and quality management system (QMS) modules across all four of its German production plants.”

As well as adopting more elements of the Plex suite, the wider geographical deployment to other sites within the Bayrak group means the company is now able to address a wider variety of operational challenges from within a single software environment.

Results

Gone are the days of siloed and ‘black-box’ software solutions, with little or no integration. The Plex software suite brings all data together to create a single source of truth for all stakeholders.

Immediate benefits include tighter inventory control, more accurate production planning, better asset integration and improved operational-data analytics and deployment.

“It is also an important step in our digital transformation,” van der Werf explains. “I believe the adoption of digital solutions should be a goal for every company. We are certainly being challenged by our customers to transform. This includes our automotive OEM customer who wants data from our machines so it can forecast and forward plan its own production systems as part of a longer digital chain.”

There are other benefits that this integrated solution offers too. “Quality, maintenance and sustainability targets are being addressed with more accurate machine operating data,” van der Werf adds. “And by removing manual, paper-based recording not only are we more efficient, but our insights are timelier and more accurate, and we can reflect this much more easily and effectively – down to product-serial-number level – in the data we send to our customers.

“Plex gives us everything we need in a single environment,” van der Werf concludes. “The relationship dynamics have changed too, with the establishment of the Plex support team in Prague, which means that the support we get is now even quicker.”

Published August 5, 2025

Featured Resources