Running a profitable manufacturing business is no easy task. When faced with a decision to either invest, sell, or close up shop, it gets even tougher.

Recently, I had the privilege of visiting Accuride Corporation’s Rockford, IL plant named “Gunite” in honor of a specific alloy the founder created back in 1854. Accuride designs, tools, and manufactures wheels and Gunite-brand wheel-end parts for commercial vehicles, and the Rockford plant has won numerous awards for manufacturing excellence including the 2015 Association for Manufacturing Excellence Award.

But back in 2011, the Gunite plant was struggling. Profits had been dropping, and management was faced with the decision to sell or close up shop. Instead, however, Accuride invested more than $60 million into the facility, which today has become a profitable operation.

So, what did Accuride do to turn this plant around?

Well, it’s never one silver bullet because as you know, the business of manufacturing is complex. In addition to the significant capital investment in new capacity and equipment, Accuride restored Gunite’s operating performance and profitability with the implementation of rigorous lean manufacturing and quality processes that touched every aspect of its operations, and a can-do cultural shift that embraced the changes and created world-class performance and a globally competitive operation. In addition, Paul Wright, Vice President of IT and CIO for Accuride, points to the Plex Manufacturing Cloud as providing a platform for the dramatic transformation that occurred.

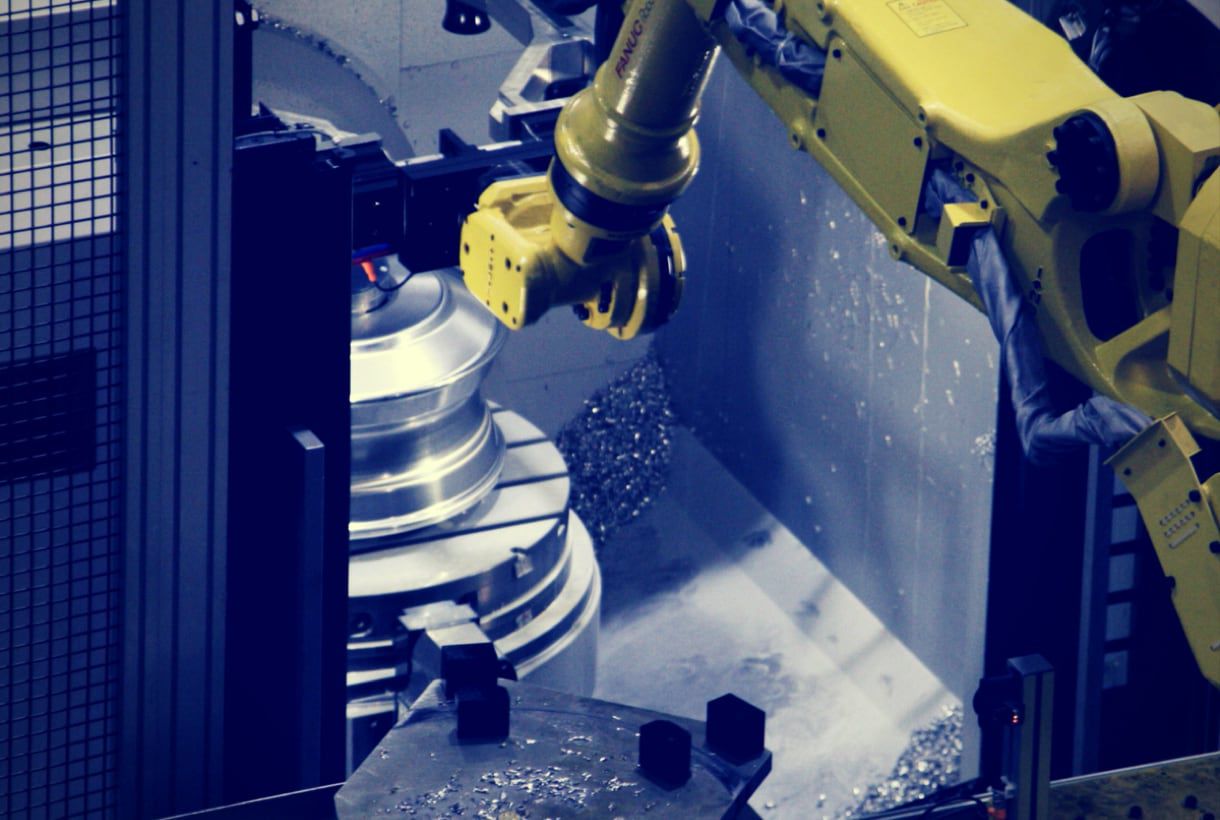

Starting in the foundry, operators utilize the most economical recipe that meets the chemical specifications which are set up in Plex. Workers adjust the molten steel mixture to meet the specifications then pour it into the casting cavities. When the parts are cool, they go through a full dimensional layout to capture real-time SPC data in Plex before going to the grinding area. The company produces multiple parts that all have different dimensions but can produce them all at the same time using a vision system and PLC to sort the various parts and robots place them on the appropriate grinder, which tracks production real time through integration of the PLC with Plex.

The company manages hundreds of SKUs so having a good scheduling system is critical. Using Kanban scheduling within Plex and barcode scanning by all personnel enables real-time production tracking so suppliers, customers, and shop floor schedulers are operating from one version of the truth.

At the distribution facility in Batavia, IL, they use Plex to stage, pick, and ship finished products to customers in the U.S. and around the globe. The distribution center used to be on an ERP system that was separate from the Gunite facility and Accuride’s other business units so getting the right parts to the right place at the right time was challenging. Now with Plex, the entire company can see all requirements in one system to optimize inventory levels, not just in Batavia but across all of the other facilities.

Today, the Accuride can produce 9,000 wheels, 2,700 wheel ends, 800 slack adjusters, and 400 hub assemblies a day. Before Plex, the company ran 35 days with on-hand inventory to fill orders but at some facilities now turns its inventory in less than 10 days, and with enhanced traceability knows it has the right parts in the right place at the right time.

Plex was also thrilled to present Accuride with a 2017 PowerPlex Impact Award for Industry Leadership. Yet another award for the company’s excellence in setting the bar high and reshaping the manufacturing industry.

Want a deeper look at what happens at Accuride’s Gunite plant? In less than eight minutes, you’ll get to see the process from smelting iron in the foundry to distribution, all narrated by Paul.

Watch the video now. Be sure to use the 360-degree directional tool in the upper left-hand corner of the video to get the full interactive experience.

Related Articles