Imagine putting on a pair of glasses that lets you see transparent, operational measurements in real time floating across your production line. With more and more companies embracing Industry 4.0 and smart manufacturing methods, that level of visibility inside an industrial environment is now a major key to a successful operation. Clear visibility keeps manufacturers on top of their operations and always in the know, turning plant floor insights into action and unlocking opportunities for improvement.

There are many reasons why manufacturers strive for more visibility in their plants, but these nine benefits will matter most to you:

- Drive Continuous Improvement – In order to push the envelope, innovate, and stay ahead of the competition, manufacturers must continuously improve their processes. By adding more visibility, manufacturers can uncover and pinpoint problem areas and address them head on.

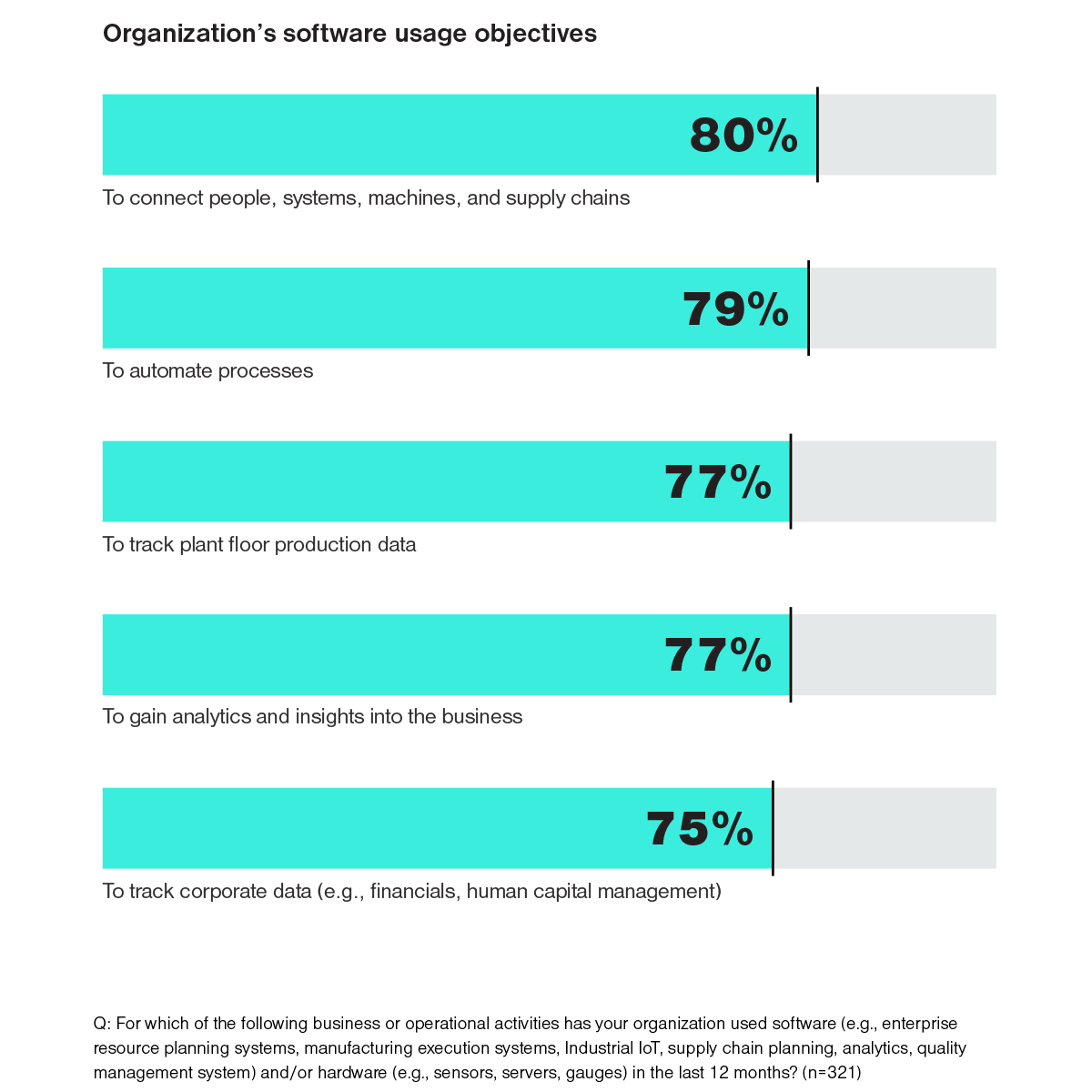

- Increase Overall Equipment Effectiveness – Overall equipment effectiveness—or OEE—is a metric that measures how well a manufacturing operation is running compared to its full potential. It’s a true measurement of productivity. By increasing visibility and analyzing processes through powerful visualizations in real time, manufacturers can improve OEE over time. As shown below, software helps track data that informs this and other visibility initiatives.

Figure 1: According to Plex's 2022 State of Smart Manufacturing report, 77% of manufacturers who are using smart manufacturing technology use software to track plant floor production data.

- Empower Operators – Operators are one of the most important parts of a manufacturing operation, and giving them visibility into things like OEE, downtime, and job performance can empower them to identify areas for improvement and increase productivity. Being able to see how a workstation is performing in real time can result in faster and more accurate decision making.

- Reduce Scrap – Having the ability to visualize real-time production metrics can bring light to major issues on the plant floor. A manufacturer with high visibility may suddenly realize that they are experiencing high scrap rates out of the blue and decide to investigate. Being able to visualize this assures that issues will be addressed before they get out of hand.

- Maximize Throughput – Throughput is such an important metric for manufacturers. It’s a clear measure of the success of an operation and one of the most important contributing factors to the bottom line. Visualizing throughput in real time can help lower operating costs by enabling quick changes to the production line if a manufacturer is not producing as many good parts as they need to reach their targets.

- Increase Efficiency – Operating an inefficient plant is bad for the environment, customers, and plant revenue. Having a clear handle of how a plant is operating gives manufacturers the information needed to ensure they are running at the highest level.

- Reduce Unplanned Downtime – The true cost of unplanned downtime is lost production, inventory, labor cost per unit, and lost capacity. Better visibility gives manufacturers insights and analytics that can help them plan and prepare for downtime and avoid being blindsided.

- Improve Quality – Higher visibility means bad parts don’t go unnoticed. Some manufacturers have so little visibility over their operations that mistakes slip through the cracks left and right. Having higher visibility means more awareness of scrap and defects, less recalls, happier customers, and better product quality.

- Meet Real-Time Operational KPIs – Many manufacturers use key performance indicators—or KPIs—to keep track of plant goals. Being able to visualize an operation against KPIs can help manufacturers stay on track and strive to reach more aggressive targets. With higher visibility, if a manufacturer is underperforming, they will be able to see it immediately and adjust their expectations or enhance their processes on the fly.

Many manufacturers struggle with a lack of visibility into their production operations. They have no way of displaying and visualizing plant data in real time, which leads to inefficiencies and lack of process control. This can result in higher production costs and the inability to meet customer expectations.

Luckily, there are solutions available that are solely designed to provide visibility through dashboards, scoreboards, and custom visualizations. Plex Production Monitoring is a lightweight, low-cost, and rapidly deployable solution that provides seamless connectivity to machines on the plant floor, delivering transparent, real-time operational KPIs to drive continuous improvements.

Ready to see clearly into your plant floor and achieve the kind of visibility that reaps these rewards? Plex Production Monitoring can make that your reality.

Related Articles