It’s been a wild ride for the food and beverage industry lately – supply roadblocks, workforce shortages, not to mention all the inefficiencies that existed before the pandemic. But what if you could be the person who alleviates these pain points for your company?

It’s not just wishful thinking; it’s smart manufacturing that connects, automates, tracks, and analyzes your operations. This industry is undergoing a revolution as technology is adopted at a rapid pace. But in a lot of companies, there’s no smart manufacturing champion. There’s no spark for positive change.

Put the bitter taste of previous unsuccessful pitches to your boss behind you. Grab key stats from the food and beverage edition of our Annual State of Smart Manufacturing Report, throw them on your boss’s desk, and kick off the conversation that’ll lead to your next promotion.

How often does opportunity knock? This stat is practically banging on your door. Take a moment and realize that barely a quarter of companies like yours are using any sort of smart manufacturing component, compared to nearly 50% of the overall manufacturing industry. This is partly why food and beverage was hit so hard during the pandemic. But now that COVID woke your competitors up, many are quickly realizing that smart technology is the way to guard against future disruptions. It’s on you to wake up your boss too.

This isn’t just fluff. Not only are most food and beverage manufacturers planning to make their operations smarter, but 57% are actively evaluating technology solutions with the intention to invest. Meaning right now as you read these words. That knock on the door we mentioned above? The opportunity won’t sit on your company’s porch for long. Show your boss why you need to leverage smart manufacturing now before you’re left behind.

So, what are food and beverage manufacturers really looking for out of technology? After a year like 2020, the answer is remote functionality. They want instant access to complete data throughout their operations from a single web browser because they know it’ll make dealing with any potential future disruption exponentially easier. Leading any smart manufacturing conversation with a major capability like this is a surefire way to grab the attention of your company stakeholders.

What year are we living in? Using manual solutions – whether they involve notepads, spreadsheets, or whiteboards – is extremely dated. That’s not the gameplan for today’s successful, efficient companies. People are taking literal vacations to space, yet your organization can’t digitize at least part of its processes? If you feel like we do, then you’ve already got what it takes to bring up the smart manufacturing conversation. After all, it’s hard to imagine your boss denying it’s time to enter the 21st century.

If you need to drive home the value of technology even further with your boss, this stat has your back. Let it sink in: 80% of food and beverage manufacturers want to adopt smart manufacturing because of what it can do for supply chains. They don’t want to repeat 2020 – they need the ability to track operations, see where ingredients are, discover why bottlenecks exist, and so much more. Your pandemic-related conversations with your boss aren’t going away anytime soon, so start steering those meetings into a smarter direction.

This is why recalls take weeks. This is why it takes days, not minutes, to trace a single ingredient throughout your supply chain. This is why there’s no warning before a machine breaks down. Without an Industrial Internet of Things (IIoT) strategy that leverages low-cost sensors, you’re speeding down the highway with a blindfold on alongside 68% of your competitors. Convince your boss to take that blindfold off and pull ahead of those other companies.

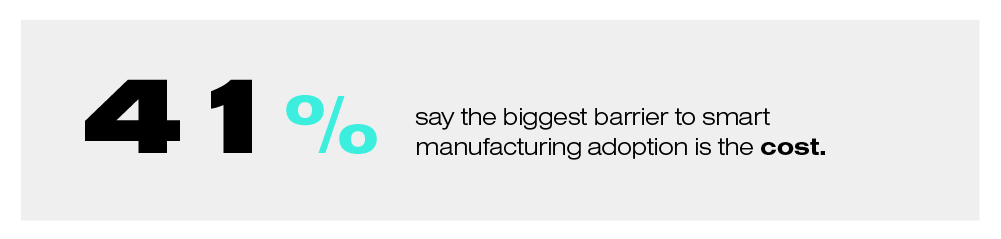

When you bring up the technology conversation with your boss, don’t let them play the “cost” card. It’s natural to have some concern about the price tag of any big initiative, especially one that promises transformation. But this fear comes from a lack of clarity around the huge ROI and laundry list of benefits that smart manufacturing unlocks. Connect the dots for your boss by describing how money and time can be saved in every corner of your operations and they’ll see the light.

You’re the future of smart manufacturing

Your company may not even realize it yet, but they’re relying on you to bring the big ideas that’ll improve operations in every sense of the word. This is how people get ahead and secure that coveted promotion (and raise). Even if it’s awkward, it’s on you to start the smart manufacturing conversation with your boss. And if these stats weren’t enough prep, we’ve got a whole reporting waiting for you.

Related Articles